Technologies

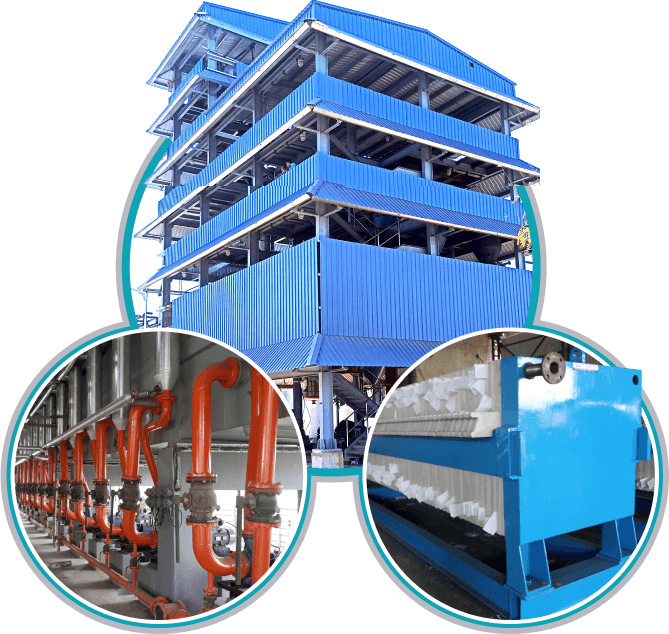

We Provide Engineering, Procurement

We excel in applying advanced technology to optimize edible oil plant manufacturing and EPC , delivering top-notch solutions for many sectors.

A Trusted Name In The Engineering Procurement And Construction Industry.

We're ISO & CE Certified, blazing trails with innovative Engineering, Procurement, and Construction solutions!

We boast technical proficiency, fortified by a team of seasoned professionals with over two decades of expertise spanning 20 countries and serving over 200 global clients. Timely project completion paired with unparalleled customer satisfaction remains our paramount commitment.

This approach underscores our reputation as a leader in our domain, forging enduring partnerships and setting industry benchmarks.

Know MoreEPC

Our expertise lies in offering EPC as a service.

We specialize in offering EPC (Engineering, Procurement, and Construction) as a full-service solution, streamlining complex projects from inception to completion.

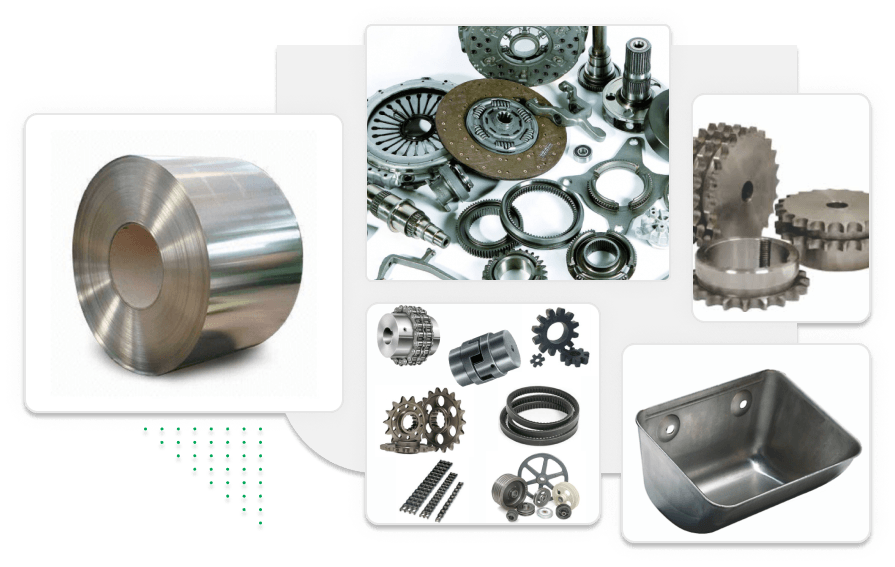

Spares

Spares as per your requirements

Customize your industroial operations with our precision-engineered spare parts, tailored specifically to meet your unique needs.

Services

Site Services

Our vast set of site services is designed to suit your construction demands from the initiation project phase

- Civil-Route Survey

- Soil Investigation

- Hydrological Studies

- Construction Management

- Quality Control

- Quantity Survey

- Safety and Training

- Commissioning and Start-up Assistance

Services

Workshop Services

We are well-equipped to offer a comprehensive set of workshop services by a qualified team in manufacturing and fabrication of the industrial equipment and vessels as per drawing and requirement.

How We Work

N and T Engitech operates by providing innovative engineering solutions and services, leveraging expertise to address complex industrial challenges effectively.

Planning & Design

Initial phase involves project conception, site selection, & architectural & engineering design.

Construction & Execution

Once the planning and design phase is complete, actual construction begins.

Finishing & Commissioning

All systems & equipment are thoroughly tested & commissioned to ensure they operate as intended.

Why Choose Us ?

We bring expertise, innovation, and reliability to every project, ensuring your vision becomes a successful reality.

Best-quality Products

Delivering the finest in quality products, our commitment to excellence is your assurance of the best

Advance Research & Development

Empowering progress through cutting-edge Research and Development, our commitment to innovation fuels the future.

Cooperative Price

Offering competitive pricing without compromising quality, we make your satisfaction affordable.

Highly skilled & qualified team

Our team comprises highly qualified and skilled personnel, ensuring precision and expertise in every aspect of your project.

On-time Delivery

We prioritize on-time delivery, so your projects stay on schedule and within deadlines.

After sales support

Our after-sales support ensures your ongoing satisfaction and success.

Our Valuable Clients

We are honoured to work with some of the leading corporations in the Engineering Procurement and Construction sector.

Projects

Completed Projects

N&T progressively provides innovative expertise to large and small businesses for a wide range of purposes and settings around the world. Examine our project portfolio.

Our Certification & Achievements

We are team of latest advanced innovative professionals who constantly gain insight into evolving EPC requirements

Experience

Clients

Best Team

Our Blog

Browse most recent blog & news from N&T. View Engineering Procurement Construction related news,and articles.