Products

High Quality Filter Press Plate Manufacturers

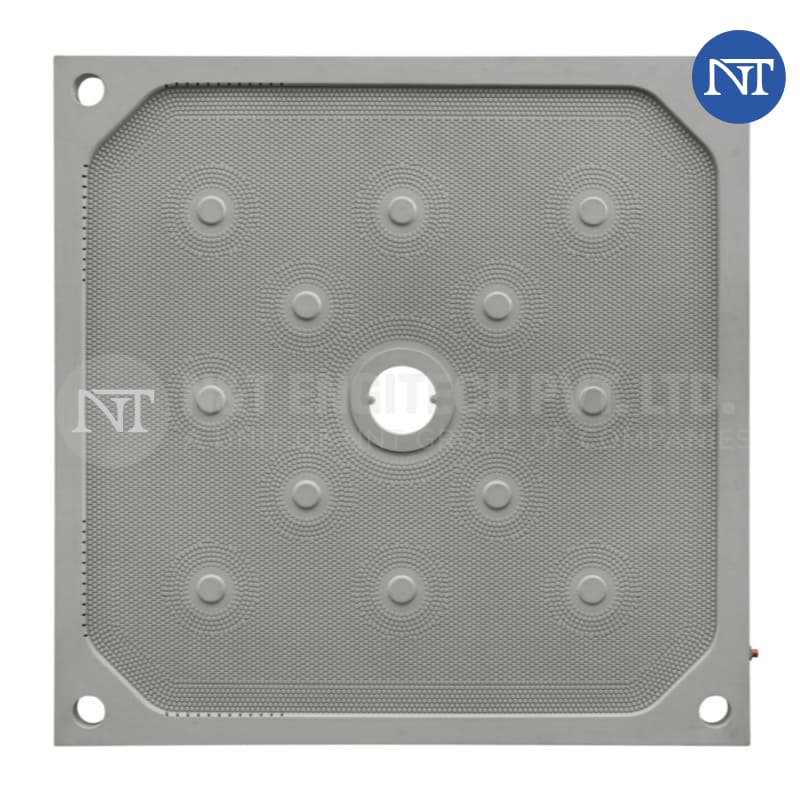

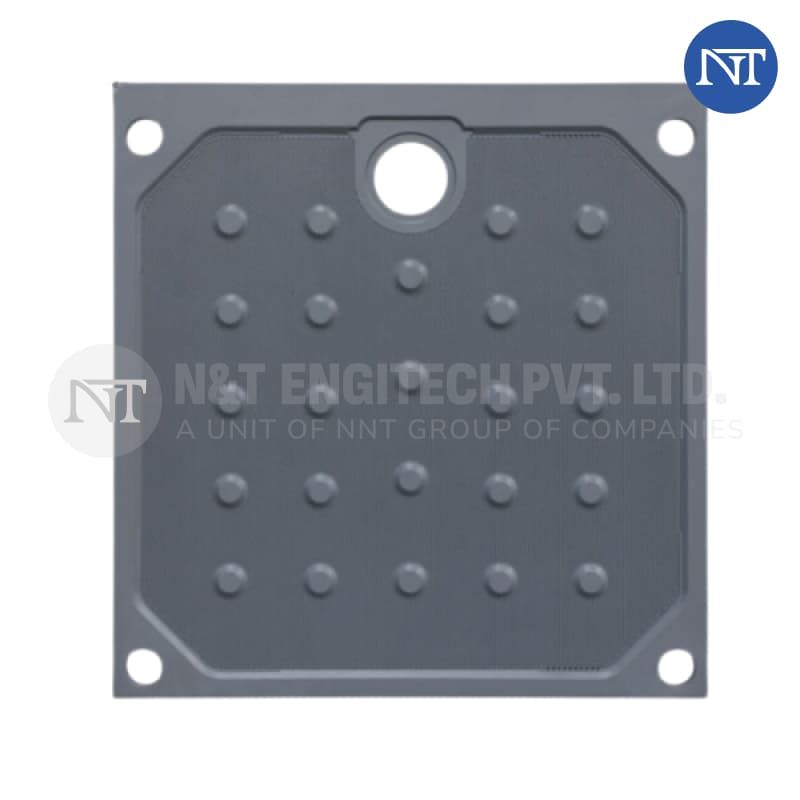

NNT Engitech is the house of premium filter press plate spare parts with customized solutions for industries. As the leading filter press plate providers, our spare parts are streamlined from best quality Polypropylene (PP), Cast Iron, Stainless Steel & other materials. These materials are chosen carefully, taking into place, the types of materials being handled & the environmental conditions around. All of our plates are designed to deliver maximum performance, durability & efficiency regardless of the industry you are in — chemical processing, wastewater treatment, food and beverage, etc. We are one of the top Filter Press Plate suppliers, and Filter Press Plate exporters with guaranteed quality availability as per global standards.

| Specification | : Details |

|---|---|

| Material | : Polypropylene (PP), Cast Iron, Stainless Steel, Cast Iron. |

| Applications | : Chemical Industry: For separating chemicals, solvents, and sludge. |

| Design | : Plate Shape: Usually square or rectangular, however depending on the system, bespoke designs are possible. |

| Durability | : Pressure Resistance: Depending on the application, it can tolerate pressures ranging from 6 bar to 25 bar or higher. |

- Built using three different materials PP, Cast Iron, and Stainless Steel, making them resistant to chemical and corrosion wear.

- They are offered in square or rectangular shape, custom made to your requirements particular to your filtration system.

- The grooves embedded on our plates are precision-engineered for secure filter cloth fastening to optimize the filtration process for further efficiency.

- Our plates are engineered for pressures from 6 bar to 25 bar or higher, providing uninterrupted service in difficult industrial conditions.

- Corrosive chemicals are no match against materials like FRP and stainless steel.

- Available in flush or diaphragm frames to meet unique filtration requirements while maintaining high performance.

Filter Press Plate spare parts are used in numerous industrial processes for properly separating liquids and solids. They are essential in sectors like chemicals, food & beverages, and wastewater treatment, where accurate filtration is necessary to ensure quality and compliance. So whether one needs these components for dewatering slurries, purifying liquids, and even treating industrial waste, they get reliable and durable performance under arduous conditions.

- For chemical solution separation, solvents, sludge

- Separation of solids from industrial wastewater

- Dewatering of Mineral Slurries

- Mining & Minerals Processing

- Purification of active pharmaceutical ingredients

- Wastewater and dye residue filtration

Filter Press Plate are utilized in a variety of industries, including

- Chemical Industry

- Mining and Metallurgy

- Food and Beverage

- Pharmaceutical Industry

- Textile and Dyeing Industry

- Ceramic Industry

- Paper and Pulp Industry

- Wastewater Treatment

- Construction and Cement

- Petrochemical and Oil & Gas

- Agriculture and Agrochemicals

- Environmental Applications

Why choose NNT Engitech?

Industry Expertise

Having years of expertise in the arena of Filter Press Plate, we know what different industries require and we cater them with high-oriented services.

Premium Materials

These plates are made from an accurate grade of Polypropylene and Stainless Steel making them durable and shatter-resistant to rust and wear.

Customized Solutions

As Filter Press Plate exporters who make custom designs based on your filtration needs, we provide the right designs that fit your needs.

Global Reach

Being one of the major Filter Press Plate manufacturers and suppliers, we possess an extensive distribution facility to supply to any corner of the world.

Commitment to Quality

Our manufacturing processes are quality controlled to provide plates that meet or exceed industry quality standards.

Comprehensive Support

Our team is committed to support from product selection to after-sales support, which means you get a seamless experience from start to finish.

How We Work

N and T Engitech operates by providing innovative engineering solutions and services, leveraging expertise to address complex industrial challenges effectively.

Planning & Design

Initial phase involves project conception, site selection, & architectural & engineering design.

Construction & Execution

Once the planning and design phase is complete, actual construction begins.

Finishing & Commissioning

All systems & equipment are thoroughly tested & commissioned to ensure they operate as intended.

Our Blog

Browse most recent blog & news from N&T. View Engineering Procurement Construction related news,and articles.